Precision Welded Frame Manufacturing

Sanmina provides design and manufacturing services for highly customized precision welded frames used in high technology applications including industrial, semiconductor, cloud storage, and medical.

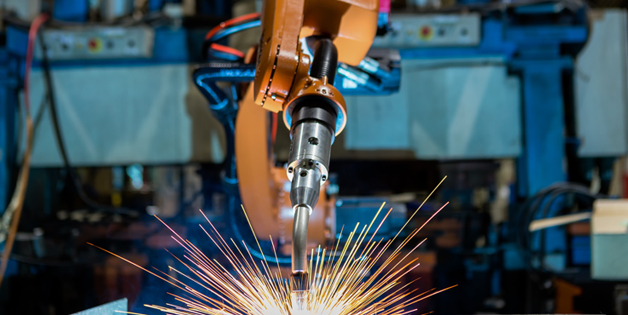

Our facilities are equipped with state of the art MIG, TIG and robotic welding. Sanmina’s experienced welding department is staffed with skilled, certified welders and a certified weld inspector. Our engineering team helps customers develop precision welded frame prototypes, achieve certifications where required and bring the products to volume production using our New Production Introduction process.

Structural precision welded frames for industrial and semiconductor applications are designed and manufactured to bear loads as high as 5,000 lbs.

Find out how Sanmina’s custom precision welded frames design and manufacturing capabilities can help you efficiently take complex products to market. Contact us