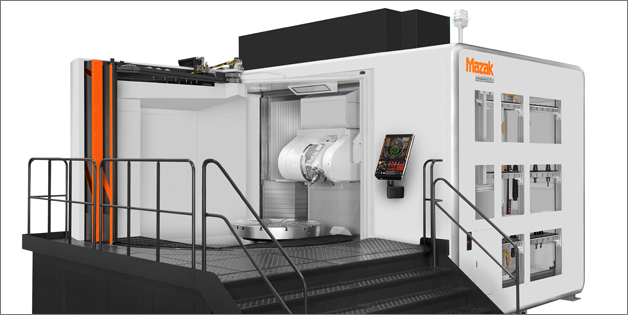

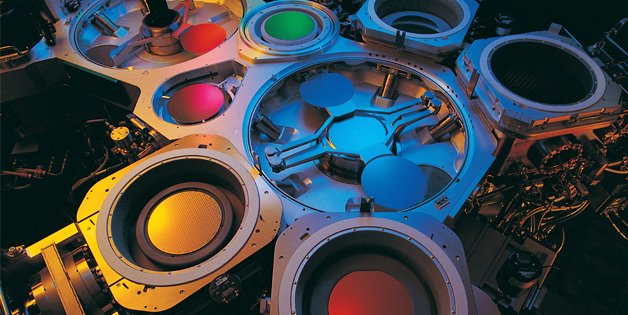

Sanmina MSD provides a complete range of design & manufacturing services for enclosures, precision machining, welded frames & systems integration. Some of the world’s best known companies in industries including semiconductor, large scale commercial printing, medical, industrial, self-service, gaming, multimedia, enterprise & cloud computing trust Sanmina to help them achieve their business goals.

Industries

Learn More

Capabilities

Learn More