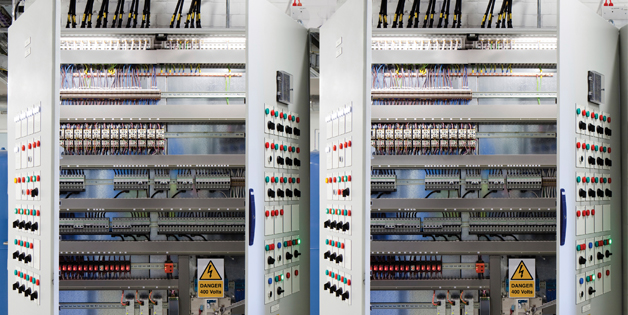

Quick-Turn Prototyping

Sanmina’s regional quick-turn prototyping facilities bring decades of product experience to help both large and emerging companies prototype high technology products. Experienced, local engineering and manufacturing teams provide fast material acquisition, process and test development, and 72 –120 hour cycle time. Sanmina’s ability to efficiently fabricate components and assemble and test complete systems simplifies the prototype process and accelerates time to market.

As a Tier 1 EMS company Sanmina provides the additional benefits of a complete, “one-stop” manufacturing solution, easy transition to regional and global manufacturing in 75 Sanmina facilities, product design, and DFx/DFM analysis.

Create a more efficient production timeline with Sanmina’s quick-turn prototyping solutions. Contact us

Discover more:

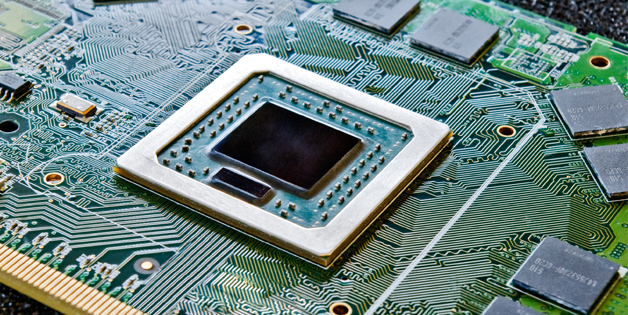

Printed Circuit Boards

Learn More

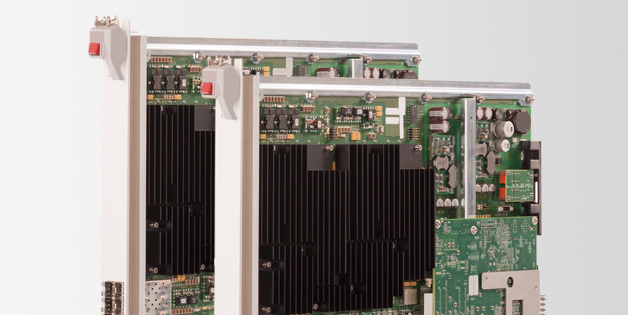

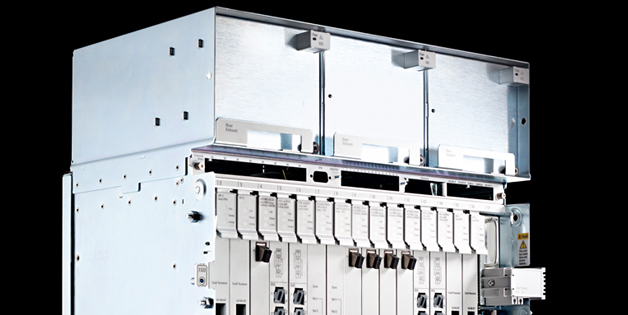

PCB Assembly & SMT

Learn More

Enclosures

Learn More