Plastic Injection Molding Design & Manufacturing

Some of the world’s best known OEMs trust Sanmina to produce their plastic components.

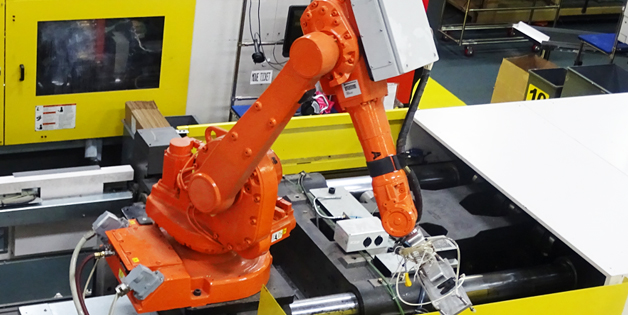

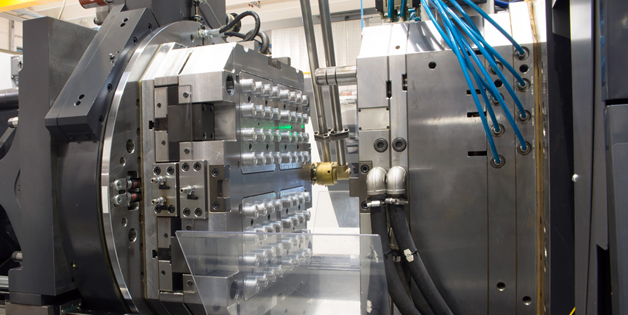

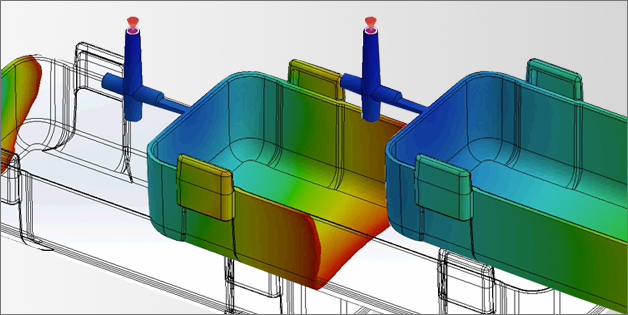

Sanmina’s plastics facility is equipped with nearly 100 plastic injection molding machines with clamping pressure ranging from 28 tons to 1,160 tons. Our experienced tooling, process, quality and resin engineers work concurrently using a scientific molding approach to develop cost effective, highly reliable manufacturing solutions for customers across a broad range of industries. Application of scientific molding combined with strategic partnerships with U.S. and Asian toolmakers enables delivery of cost-effective, very high quality plastic manufacturing solutions.

See how Sanmina can deliver cost-effective injection molding services. Contact us