Precision Machining

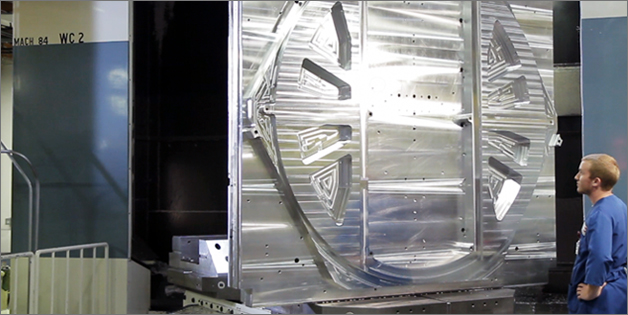

Sanmina provides customers with the world’s most advanced precision machining capabilities. Our facilities located in Newark and Fremont, California; Austin, Texas; & Ma’alot, Israel manufacture machined components and sub-assemblies and integrate them into complex medical, semiconductor and other industrial systems.

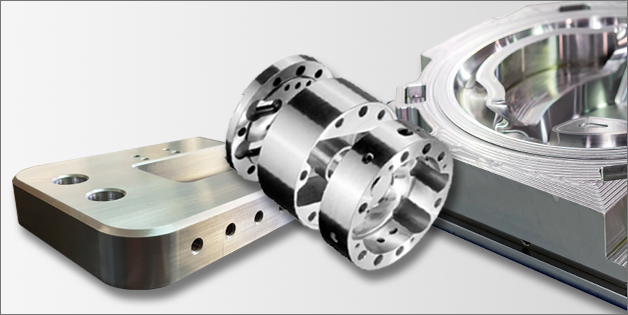

Customers benefit from a comprehensive machining service for highly complex systems including small, medium and large format precision machining combined with turning, milling and post machining processing services. In addition to in-house precision machining capability, Sanmina has developed a network of high technology partners to provide special processing including custom plating, anodizing, coatings, brazing, e-beam welding and lapping.

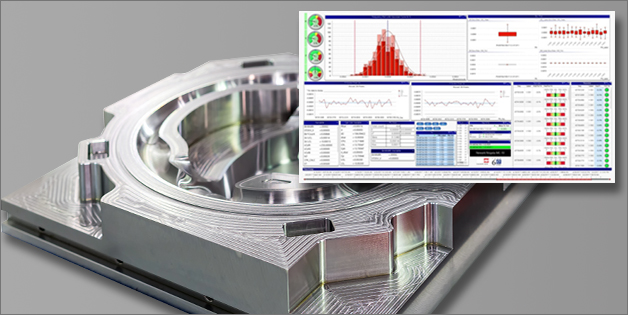

Ongoing investment in the latest manufacturing technologies, including 5-axis machining, provides customers with the most advanced precision machining capability. Equipment and processes are standardized around the world to facilitate easy transfer of products and best practices between facilities. Sanmina utilizes a proprietary real-time SPC data analysis system integrated directly into CNC Machines to ensure reliable process control.

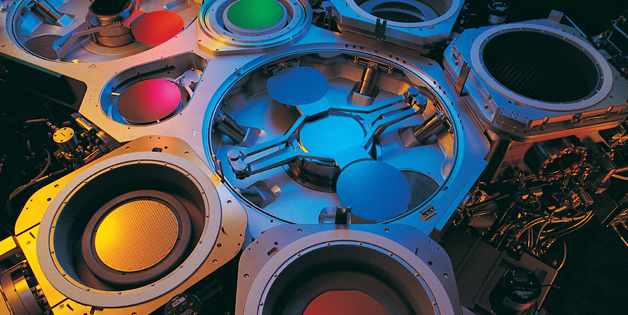

Our systems assembly and test teams have decades of experience integrating machined components and sub-assemblies into advanced systems with multiple complex technologies including robotics, motion control, fluidics and electronics. Sanmina also has on-site cleanroom assembly and Residual Gas Analysis testing facilities used to monitor contamination levels in advanced semiconductor vacuum systems.

Combining precision machining services with welded frame manufacture, enclosure fabrication and systems integration provides an end-to-end integrated manufacturing service.

Learn how Sanmina’s precision machining capabilities can help you take complex products to market. Contact us