設計・エンジニアリング

世界17か所のデザインセンターに、500名以上の製品設計エンジニアとシステムソフトウェアエンジニアを配置。主要産業分野別、個々のコンポーネント分野別に、広範囲に亘る市場と技術の専門知識を提供いたします。

> 詳細情報

NPI( 新製品立ち上げサポート)

世界各地のお客様の近くにあるNPIセンターにおいて、試作、評価、製品立ち上げのサービスを提供します。世界中の主要地域での量産立ち上げ、また最適なコストを実現できる地域への製造移管も推進いたします。

> 詳細情報

サプライチェーンマネジメント

広範囲に亘る認定サプライヤ、人的リソース、資産の有効活用等に関し、グローバルサプライチェーンの専門家がお客様に様々なメリットを提供いたします。

> 詳細情報

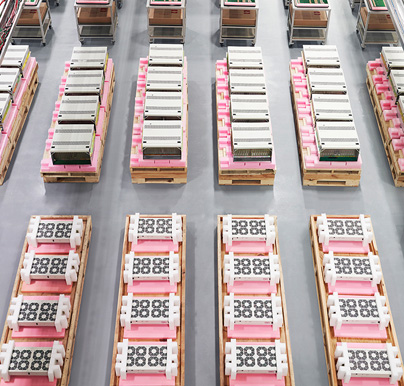

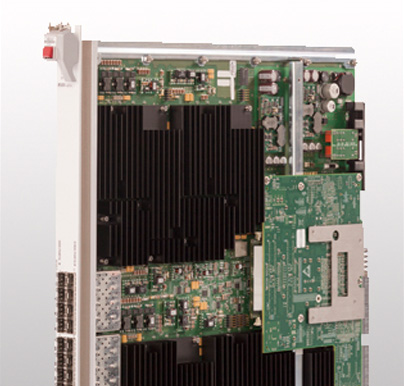

製造

世界有数の企業にご満足頂いている機構部品を含む受託製造企業として、多岐に亘る最先端技術に対応いたします。

> 詳細情報